Paper Reel Transportation Optimised with Non-Slip Fabric

Non-Slip Fabric

At Heskins, we take safety seriously, and we are committed to assisting hauliers, paper reel manufacturers, and distributors in conforming to EN12195-1:2010 standards. These standards are designed to address the safe transportation of paper reels and reduce associated safety risks. This initiative has gained prominence not only within the industry but also with regulatory bodies like the DVSA and the RHA. We understand the importance of these standards and have solutions in place to help you meet them effectively.

Understanding EN12195-1:2010

EN12195-1:2010 is a set of standards that specifically focuses on the secure transportation of goods, particularly non-slip paper reels. To get the full details, you can download the standard from CEPI (Confederation of European Paper Industries) or other reliable sources. However, we’ve outlined the relevant section below and provided insights into how Heskins products can assist those involved in paper roll handling to meet EN12195 standards.

Heskins Non-Slip Fabrics: Ideal for Paper Roll Handling

Our non-slip fabrics are tailor-made for this application. We offer self-adhesive grip material variants that adhere securely to surfaces, ensuring that paper reels stay in place during transportation. These fabrics not only provide excellent grip but are also versatile. They can be reused if their integrity is maintained, but they are cost-effective enough to be used as one-time solutions when needed.

The Popular Choice: H4643

One of our most popular options for securing paper rolls is the H4643. We supply it in 150mm wide strips, and the length can be customised to your specific requirements. What sets our products apart is that they all exceed the Coefficient of Friction requirement for paper roll handling, which is μ0.6. This means that our strips provide an exceptional level of grip, ensuring the safety of your cargo during transportation.

Proper Application is Key

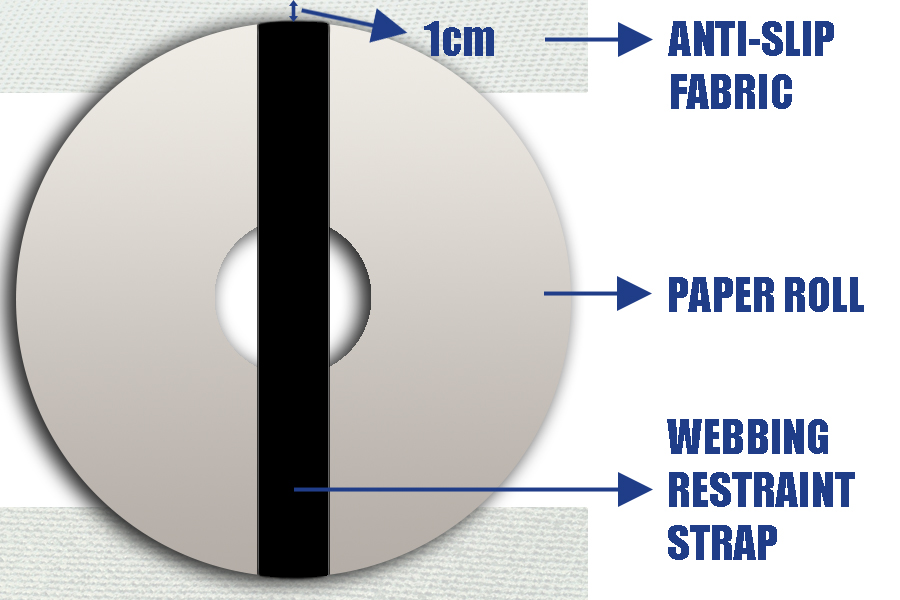

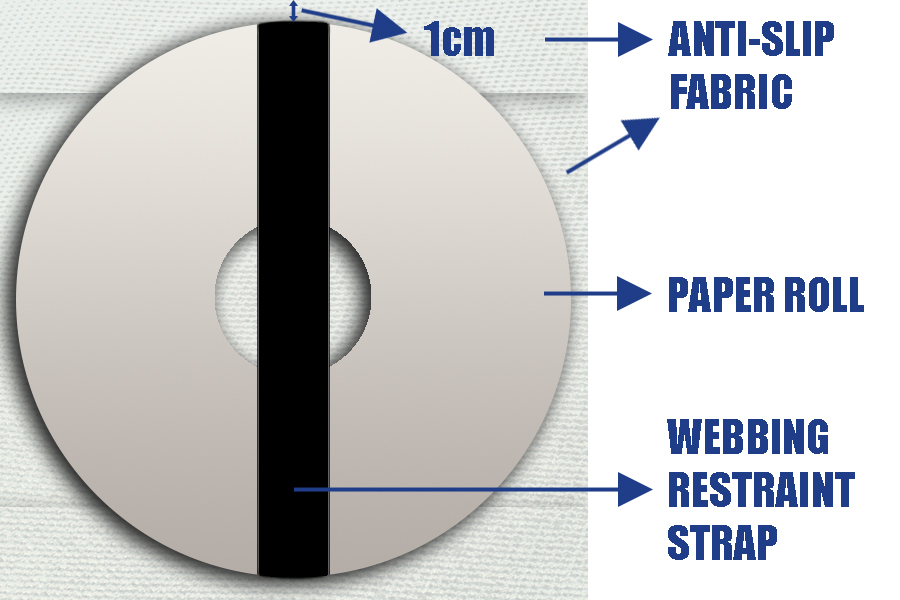

To meet EN12195 standards effectively, it’s crucial to apply the strips correctly. They should be positioned under the paper reels to expose an ideal outer uncoated strip of approximately 1cm. Additionally, strips should be placed underneath the back reels to prevent backwards slipping. Proper application not only enhances safety but also ensures compliance with the standards.

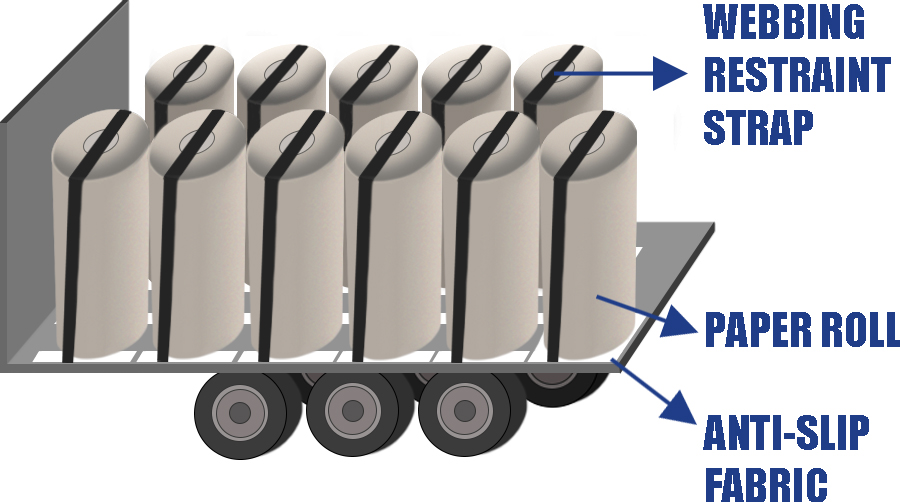

We’ve provided diagrams to visually demonstrate how self-adhesive grip material, such as our non-slip fabric, is used to secure paper reels during transportation.

In Diagram 1, you can see how the material is effectively applied to ensure safe transportation.

Diagram 2 illustrates the proper way to secure the two paper reels at the back of the truck using anti-slip fabric. Additional pieces are placed underneath to prevent the reel from touching the floor of the truck, providing added security, especially on inclines.

In Diagram 3, you can observe the interior of a lorry where the paper reels are correctly secured using non-slip fabric along with self-adhesive grip material and webbed restraint straps. This comprehensive approach ensures that the cargo remains stable and secure during transit.

Reach Out for Expert Guidance

We are here to assist you every step of the way. If you need further guidance, our knowledgeable team is always ready to share their expertise freely. Safety is our priority, and we are dedicated to providing you with effective solutions to meet and exceed EN12195 standards.

In conclusion, adhering to EN12195-1:2010 standards is crucial for ensuring the safe transportation of paper reels. Heskins offers top-quality non-slip fabrics with exceptional grip properties to help you meet these standards effectively. We are committed to enhancing safety in the industry and look forward to assisting you with your paper roll handling needs. Feel free to reach out to our team for further assistance and information. Your safety and the safety of your cargo are our utmost concern.